7 Tips for Reducing 3D Printing Stringing

- Mesh Mayhem

- May 6, 2023

- 3 min read

Updated: May 13, 2023

3D printing stringing can be a frustrating issue that can affect the quality of your prints. It's important to take the right steps to reduce stringing to maintain the best possible printing results. PTEG is very well known for its stringing but is a great material if you can master these tips. Here are 7 tips for reducing 3D printing stringing:

1. Increase the Nozzle Temperature:

Increasing the nozzle temperature can help reduce stringing by allowing the plastic to flow more easily. It's important not to increase the temperature too much, as it can cause the plastic to melt too quickly which can lead to other issues. Purchasing a Thermometer Digital Infrared is a good idea to help make sure your nozzle is working properly.

2. Increase the Retraction Distance:

Retraction is when the filament is pulled back from the nozzle before starting a new layer. Increasing the retraction distance can help reduce stringing by reducing the amount of plastic that is left behind the nozzle.

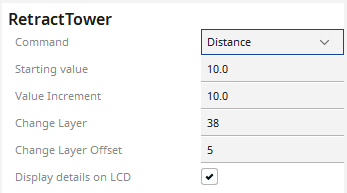

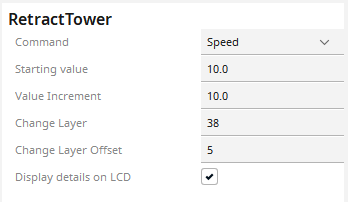

A simple retraction tower test can help you figure this out. If you are using Cura, you can simply add the plugin and modify the g-code. Every machine and filament is different, one setting may be good for one but not the other. So it's a good idea to make separate profiles to match your prints.

First start with the maximum speed you want and the lowest distance (2 is a good start)

Next, add your value increment, I recommend a .5 to 1.0mm increment.

This increment change will happen at the change layer. (On this test from Cura you can see the layer change occurs at layer 38.)

Run your slicer and print your test print. Repeat the process if necessary. Your starting value would change to where your final increment ended on your previous test.

After you are satisfied with your final choice. you can now play with the speed or leave it alone.

Download a free retraction tower stl here.

3. Reduce the Print Speed:

Reducing the print speed will help reduce stringing by giving the plastic more time to cool down before it is deposited. It's important to not reduce the speed too much, as it could lead to other issues such as layer shifting, and poor adhesion, and cause stringing in itself. Not to mention longer print times.

4. Increase the Cooling Fan Speed:

Increasing the cooling fan speed can help reduce stringing by cooling the plastic faster and preventing it from drooping. It's important to not increase the speed too much, as it could cause the plastic to cool too quickly and lead to other issues.

5. Reduce the Flow Rate:

Reducing the flow rate can help reduce stringing by reducing the amount of plastic that is being extruded. It's important to not reduce the rate too much, as it could cause the plastic to not be extruded properly and lead to other issues.

Normally you would not have to change this but in certain cases like stringing, it can be a very useful tool.

Example: If you are pushing too much material you can lower the percentage here to %75 for a -.5mm offset or if you are not pushing enough material, you could increase it to %125 for a +.5mm offset. It is recommended to use this as a last resource as it can cause prints to fail

6. Increase the Z-hop Distance:

Stringing is a common issue when 3D printing, and it occurs when there is too much plastic between each layer. Changing the Z Hop setting can help reduce this issue. Z Hop is a setting in a 3D printer's slicer software that controls how much the nozzle will lift when it moves between layers. Increasing the Z Hop value will reduce the amount of plastic that is deposited between layers and thus reduce the amount of stringing. If the Z Hop value is set too high, it can cause poor adhesion between layers and cause a poor-quality print, so it is important to find the right balance.

7. Enable Coasting:

Enabling coasting in Cura can have many benefits. First, it helps to reduce the amount of plastic being used when printing. By coasting, the printer will move to the next point before turning off the extruder, allowing the hot plastic to continue flowing and creating a smoother finish. This can also reduce stringing and the need for support. Additionally, coasting can reduce the amount of time spent printing, as it eliminates the need to retract filament and can help to improve print speeds. One of coasting's best features is coasting can help to reduce the amount of noise created by the printer, as it eliminates the need for retraction and unretracted.

By following these steps, you should be able to reduce the amount of 3D printing stringing that you experience. It's important to remember to experiment with different settings to find the best combination for your printer and filament.

Helped a lot thanks!